Let’s discover when tradition inevitably must make way for innovation.

After being extracted from olives, extra virgin olive oil appears veiled and opalescent. That’s because water and solid fragments are suspended in the oil in variable quantities depending on the extracting method and quality of the olive oil mill.

You must have noticed this residue at least once, as it’s usually quite evident, principally because it tends to sediment in the bottom of the storage tank or simply your aunt or grandma’s oil jug.

That’s not a good sign at all! The coexistence of water, nutrients, and microorganisms may shortly lead to sensory defects such as oily deposits and rancidity.

But specifically, what happens? Water, dust, dirt, proteins, enzymes, and all the suspended substances made of olive fragments, olive stones, leaves, and impurities in general, are highly reactive and can trigger degradation phenomena in olive oil.

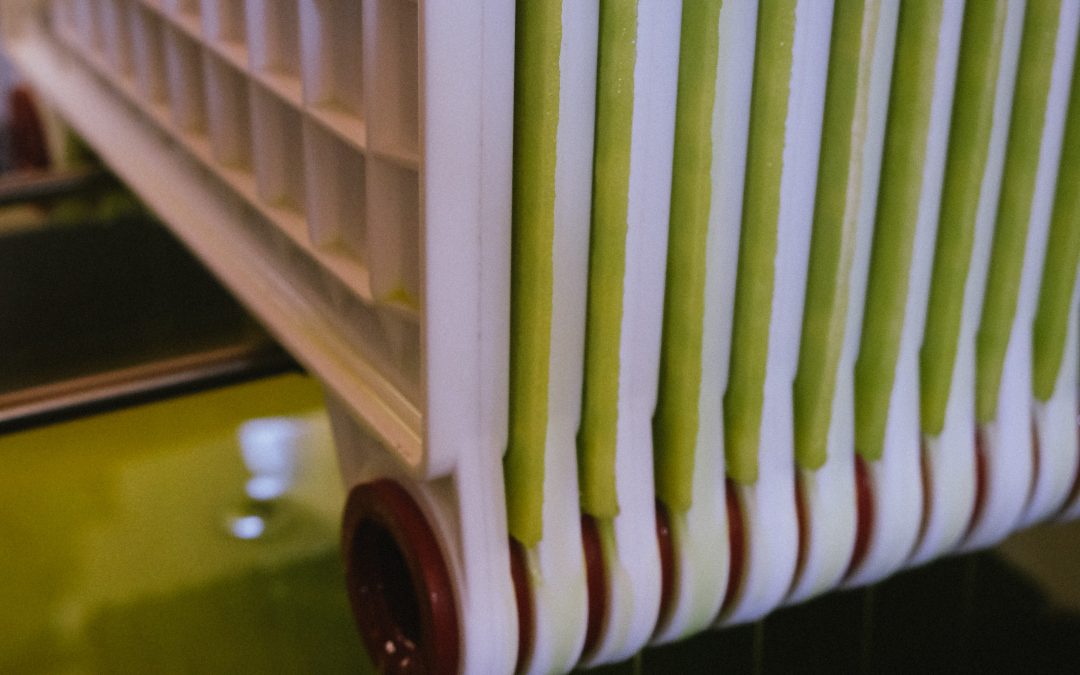

How to prevent this? Making the oil pass through a porous mean (usually paper filters), foreign matter and water molecules are held back and are de facto removed from the oil. When we separate the compounds involved in chemical reactions, we avoid the onset of defects, at least in the short term. So, through filtering, we obtain an undoubtedly more stable, limpid, and longer-lasting product.

That’s why filtering olive oil extends its shelf life! We would stress that filtration is aimed only to ennoble extra virgin olive oil even more; this further step implicates expenses in terms of equipment, labor, or even just the simple and inevitable loss of product. In fact, in each filtration session, a certain amount of oil remains stuck in the filters pressed in the machine, and it is released only at the end of the process (as clearly visible in the video). The oil falling from the filters is collected in the drip tank and then eliminated.

A loss in quantity totally justified by a remarkable improvement in quality!

What do we do, then? Let’s filter it!